ABOUT US

PMS was founded in 1979 as a manufacturer of pharmaceutical machineries. Our product lines have been gradually extended to cosmetic, food and chemical machineries. Following the success of the first factory, we established the second manufacturing facility in 1987. PMS continues developing new products and improving the design and operation through research, advanced technology and machineries, to serve the expanding demand of global industry. As a customer-oriented company, PMS is committed to offer high quality machineries and services to achieve utmost customer satisfaction. Our highly qualified and experienced team of design engineers and technicians are responsible for providing ideal solution, tailored to suit customer’s need. We aim to be more than just a supplier. We seek to be a partner of our clients.

HIGHLIGHTED MACHINES

THAI COATER

Thai Coater is a leading manufacturer of high-quality coating machines for the pharmaceutical industry. We specialize in providing cutting-edge coating solutions that help pharmaceutical companies improve their tablet coating processes and increase productivity. With our advanced technology, we can reduce coating time by up to one third for most customers. Our machines have a capacity of 2 to 400 kg, and we offer customization options to meet unique needs.

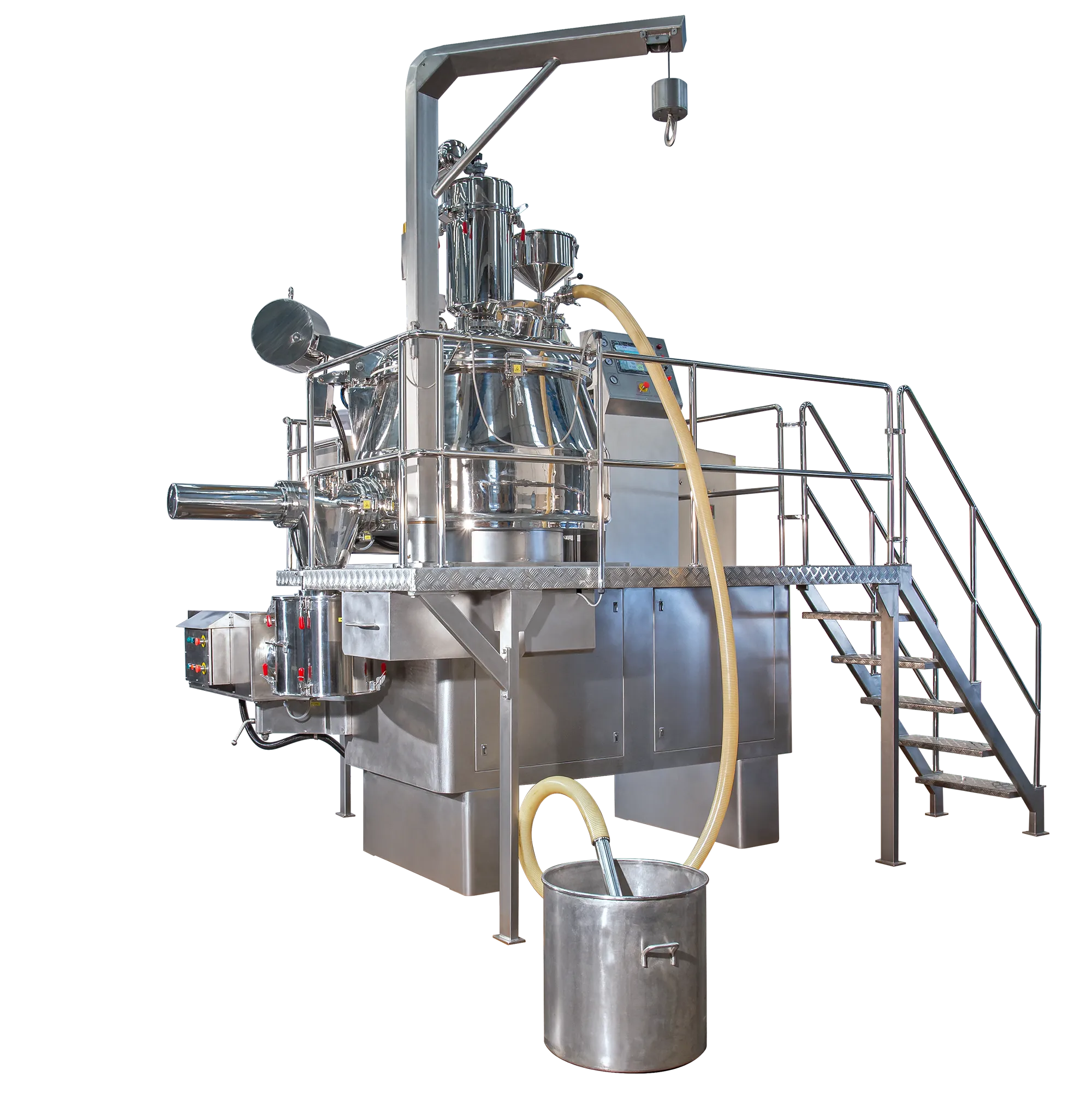

HIGH SPEED MIXER

PMS Mixer is a powerful machine that combines mixing, dispersing, and high-shear granulating into a single operation with an optimal cycle time. With this machine, dry mixing can be achieved rapidly, typically within 1-3 minutes, while wet granulation can be performed in just 3-6 minutes. This means faster processing times and increased productivity for pharmaceutical companies. PMS offers batch size between 1 to 1250 L.

HAMMER MILL

The PMS Hammer Mill is a versatile impact mill that's perfect for reducing particle size and fine grinding of dry materials. With customizable features such as the rotor speed and screen size, the customer can control the particle size and throughput of the ground material to meet your specific needs. We offer capacity up to 300 kg per hour.

GRANULATOR

The PMS Granulator is a versatile and compact machine that can be used for both wet and dry granulation simply by changing the granulation head set. Designed to comply with GMP requirements, this granulator ensures that product contact parts are completely separated from technical components, making the operating chamber oil and grease-free. Its main functions are to reduce particle sizes of agglomerates to a desired dimension and to improve particle size distribution. You can control the desired particle size by selecting the appropriate screen mesh and gap setting between the rotor and screen.

VACUUM FEEDER

PMS Vacuum Feeding Machine is an efficient solution for transferring materials from one process to another in a contained and dust-free environment. The vacuum transfer system is suitable for a wide range of applications in the pharmaceutical, chemical, and food industries. The machine is designed to handle powders, pellets, and granules of various sizes, and it can be customized to suit specific requirements. Vacuum Transfer Machine helps to maintain a clean and safe working environment by preventing contamination and dust emissions during material transfer.

CONTAINER BLENDER

A container blender, also known as an intermediate bulk container (IBC) blender, is a versatile machine that is widely used in pharmaceutical, food, and chemical industries. This type of blender is designed to blend powders, granules, and other materials inside an IBC. One of the key advantages of a container blender is its ease of use. The IBC is loaded onto the blender, and the mixing process begins automatically, saving valuable time and labor. The blender is also equipped with advanced control systems, allowing for precise and consistent mixing. Container blenders are designed to be easy to clean and maintain, making them a cost-effective solution for many applications.

TUMBLING TYPE MIXER

PMS provides a wide range of Tumbling Type Solid Mixers, including Cube Mixers, Vee Mixers, and Double Cone Mixers. These mixers utilize rotation around a central axis to blend materials thoroughly and uniformly. They are suitable for gentle blending of dense powder and granules and have been recognized as highly efficient and cost-effective tumblers due to their durability and minimum maintenance requirements. Our product series encompasses systems that operate on a laboratory to a production scale, with working capacities ranging from 10 to 2,000 liters.

LIQUID MIXER

PMS also offers Liquid Mixing Tanks and Reactors, which are critical pieces of equipment for Chemical, Pharmaceutical, and Food Processing Industries. PMS can Design, Customize, and Manufacture many kinds of Tanks to match the unique requirements of the Clients. We can facilitate chemical reactions, such as mixing, blending, and heating, under controlled conditions by using various mixing techniques, such as turbine, propeller, or paddle, to ensure uniform mixing and blending. PMS offer between 10 to 6,000 liters of Mixing Tanks.

PMS OVEN

PMS Hot Air and Sterilizing Ovens are operated by generating heated air and circulate it throughout the drying chamber. They are essential pieces of equipment that are used to dry products or equipment in pharmaceutical, food, and cosmetic industries. PMS provides solution to economical, fast and efficient drying of a wide variety of material in powder, granule, crystalline, filter cake and fresh herb form. The design ensures consistent and perfect drying result. The oven, built to a modular design, can be supplied with tray capabilities ranging from 100 to 500 liters per batch. PMS can also offer the customized solution for the clients.

CREAM MIXER

PMS offers a combination of counter-rotating paddle agitator and internal homogenizer. Gate-type agitator with cross baffles rotates in anti-clockwise direction while counter paddle revolves in clockwise direction, generating a disturbance in the normally circular flow pattern and dampen vortex formation. PMS Cream Mixer applicable for a wide variety of viscosity product, i.e. emulsions and semisolid. It integrates mixing, vacuuming, heating, cooling and homogenizing functions into single machine, resulting in a considerably reduction in cycle time. Our range stretches from laboratory model of 10 liters up to production model of 6,000 liters working capacity.

FLUID BED DRIER

PMS Fluid Bed Drier is a rapid industrial drying equipment that is used to dry a variety of materials in a continuous and efficient manner. The dryer operates by using a fluidized bed of air to suspend and transport the materials being dried. The fluidized bed is created by passing a stream of air through a perforated bed of material, which causes the material to become fluidized and suspended in the air stream. The machine offers several advantages over the conventional hot air oven, including faster drying time, uniform drying, less energy consumption, and improved product quality. PMS offers the capacity from 1 to 500 kg / batch.

ENGINEERING SOLUTIONS

PMS also specializes in designing and manufacturing new machines according to the specific requirements of our clients. We have successfully completed numerous projects for small and large companies in various industries, such as pharmaceutical, food, chemical, animal feed, health food, medical product, consumer package goods, herbal product, and petrochemical. Our portfolio includes a wide range of machines, from small CIP Skid Yogurt Coating, Peanut Coating, Hybrid Drying Oven, and various types of grinders, Fixed Bed Reactor, Distillation Column, Liquid Mixing Line, and Small Chemical Plants.

18/88-89 M.6 Khok Krabue, Mueang

Samut Sakhon, THAILAND 74000

Phone: +66 2 284 2159 TO 62

Email: [email protected]

© 2020 PMS. All Rights Reserved