THAI COATER

High Efficiency Automatic Tablet Coating Machine

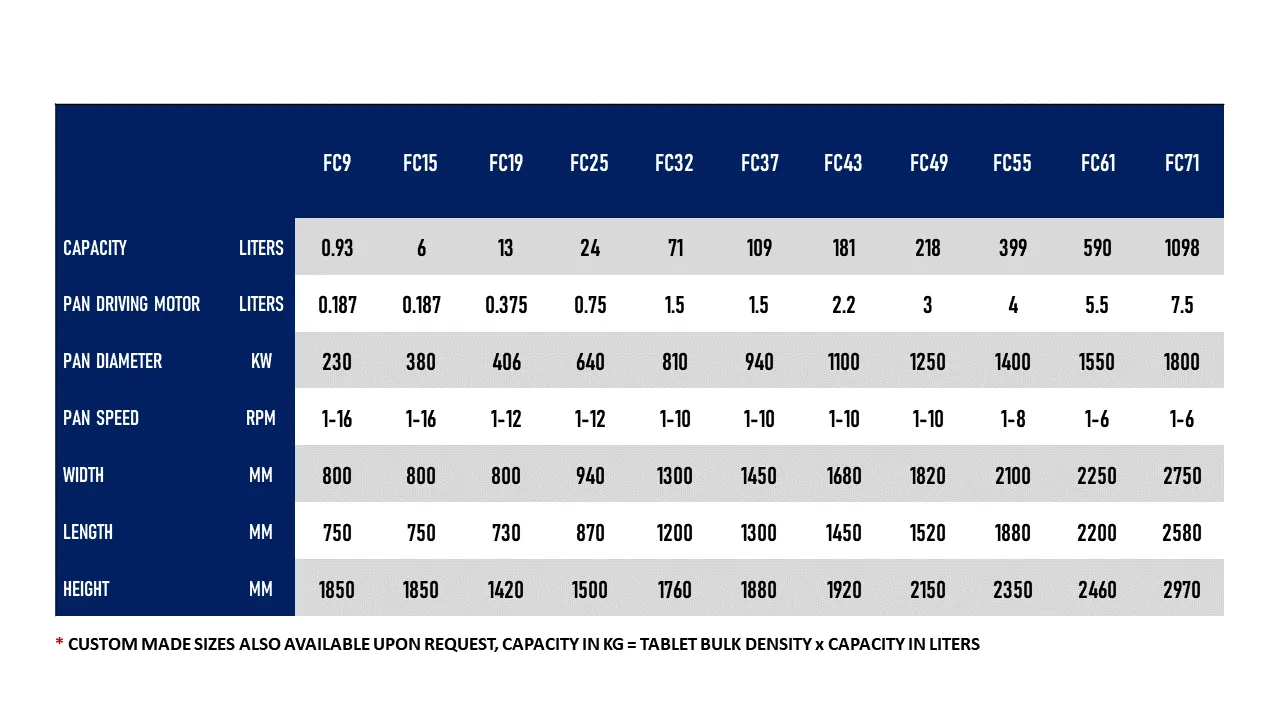

THAI COATER® delivers highly efficient coating processes for use in pharmaceuticals, food, agricultural, and allied industries. Our series of systems range from laboratory scale up to production, with capacities from 2 kg to 660 kg.

THAI COATER® ensures rapid and effective drying of sprayed core materials, resulting in optimal processing times and favorable coating results. Our systems are available in manual and fully automated processing options, with explosion-proof versions, advanced accessories, and validation services available upon request. We also offer a dedicated sugar-coating system or the option to append it to our film coating system for versatility.

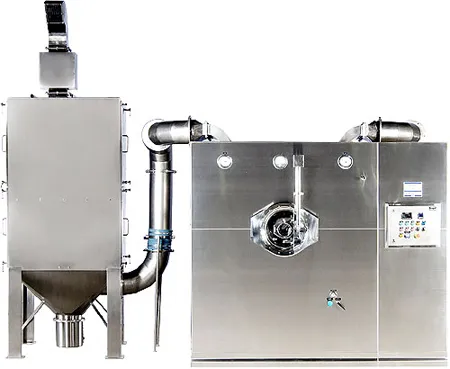

THEORY OF OPERATION

Our Coating Pan features a perforated stainless steel drum that rotates on a horizontal axis. Equipped with built-in baffles, the pan promotes uniform coating and prevents core materials from sticking together during the coating process.

The core materials are coated by our spray distribution system, which continuously sprays onto the pre-warmed core materials as they rotate in the coating pan. We harmonize the volume and temperature of the inlet air with the spraying speed to ensure that the core materials remain at a stable temperature throughout the process.

Our preconditioned inlet air, which is conditioned to the most suitable to our customer requirements in term of Temperature, Humidity and Cleanliness, is circulated through the pan, drying the coated tablets, and subsequently exhausted through filter and duct.

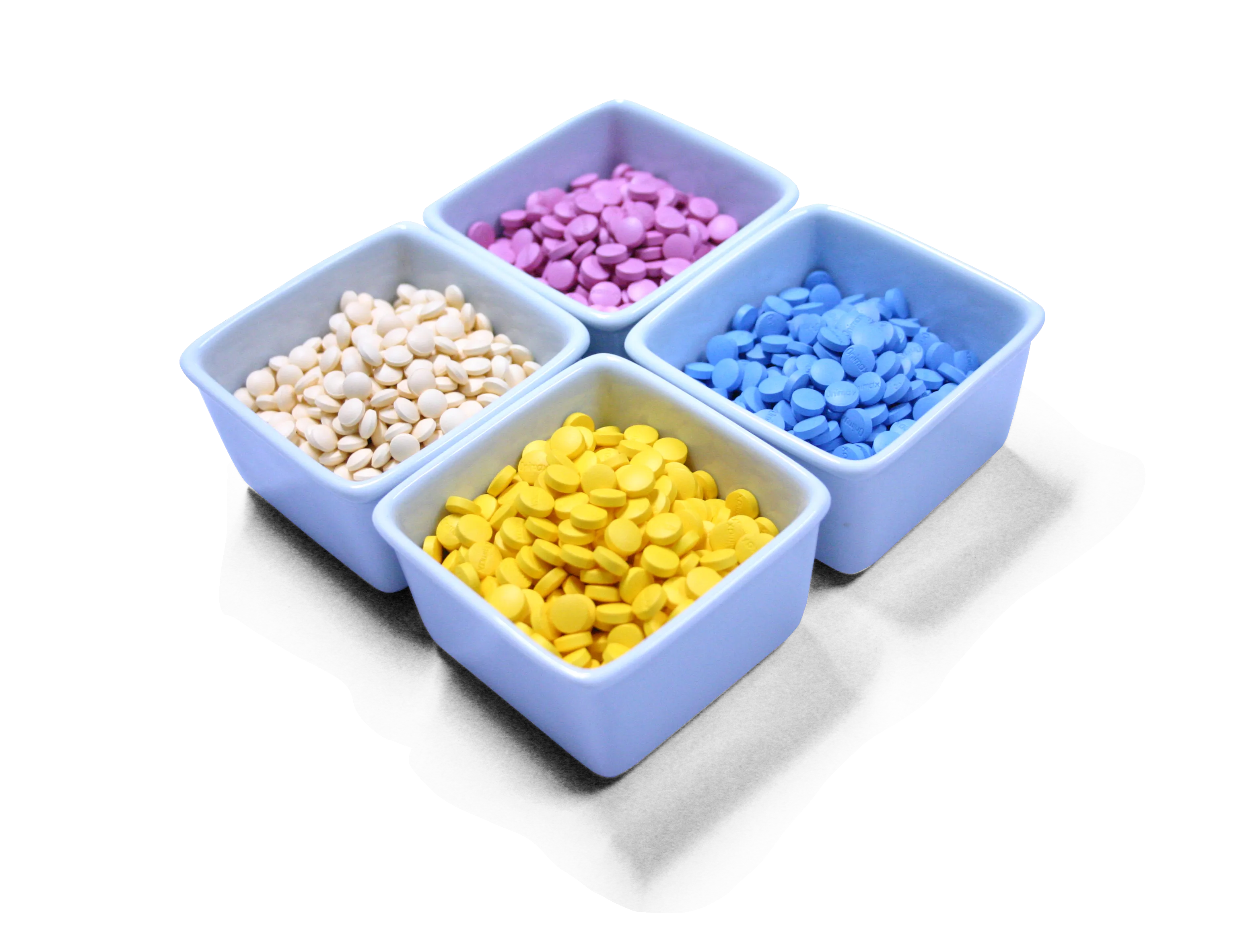

APPLICATION

Pharmaceuticals: Film Coating with Aqueous and Organic Solvent, Enteric Coating, Sugar Coating

Health Foods & Supplementary: Film Coating with Aqueous and Organic Solvent, Enteric Coating, Sugar Coating

Food: Snack, Chewing gun, Candy, Health food

Agricultural: Feed, Seed (Nutrient coat or Insect protection coat), Rice, Fertilizer (Slow release pellet)

BENEFITS

TECHNICAL DATA

STANDARD

Coating Pan and All Contact Parts made of Stainless Steel SUS AISI 316

Adjustable Coating Pan Rotating Speed

Inlet Air Handling Unit with Pre-Filter, Medium Filter, and HEPA Filter

Electrical Heater or Steam Heat Exchanger

Explosion Proof (Increased Safety) for Pan Motor

Non-Explosion Proof Motor for Exhaust and Inlet Pan

Non-Explosion Proof Control Unit

Peristaltic Pump and Spray Guns

Coating Solution Holding Tank with Pneumatic Stirrer

Reverse Pulse Jet Dust Collector for Exhaust Filter

Touch Screen and Programmable Logic Controller

OPTIONS

Explosion Proof System

Audit Trial as per CFR 21 Part

Dehumidifier for Inlet Air (Chilled Water or Refrigerant Types)

Paper or Paperless Recorder

Automatic Discharging System

Special Charging Device

Washing in Place (WIP)

Sugar Coating Equipment

Validation Documents: Installation Qualification / Operational Qualification

18/88-89 M.6 Khok Krabue, Mueang

Samut Sakhon, THAILAND 74000

Phone: +66 2 284 2159 TO 62

Email: [email protected]

© 2020 PMS. All Rights Reserved