PMS Granulator

Versatile Wet and Dry Granulator

PMS Granulator® is a compact and versatile machine used for wet and dry granulation, complying with GMP requirements and ensuring a clean operating chamber. Its main functions are to reduce particle sizes of agglomerates to a desired dimension and improve particle size distribution by using precise control over screen mesh selection and gap setting. The granulator applies continuous shearing force to agglomerates, pressing out granules through wire mesh for dry granulation or a cylindrical shredder for wet granulation. Refined particles are then discharged through the bottom port into a product container.

Overall, PMS Granulator® is a reliable and efficient machine that can greatly improve the efficiency of particle size reduction and granulation processes, while ensuring a high level of quality and compliance with industry standards. PMS offers 4 Sizes of the Machines to accommodate from laboratory use to large production.

INTERCHANGABLE HEAD FOR WET & DRY GRANULATOR

THEORY OF OPERATION

The operation of wet and dry granulators is based on the principle of particle size reduction and agglomeration. Both wet and dry granulation can be performed using a variety of granulator types, including high-speed mixers, oscillating granulators, and fluid bed granulators. The choice of granulator type will depend on the specific characteristics of the materials being processed, as well as the desired granule size and production capacity.

PMS offers a compact machine that can be used for both wet and dry granulation processes, making it a valuable tool for many industries. It is designed to comply with Good Manufacturing Practice (GMP) requirements and ensure that product contact parts are completely separated from technical components, providing a clean and oil/grease-free operating chamber.

In wet granulation, a liquid binder is added to the powder mixture to create a moist mass. The mixture is then forced through a to create granules of the desired size. The liquid binder helps to form the granules and acts as a binding agent.

In dry granulation, the powder mixture is compacted and then crushed or milled into granules of the desired size. No liquid binder is added, but the pressure and compression forces applied to the powder mixture help to agglomerate the particles and create the desired granule size.

PMS Granulator® is a versatile and compact machine that can be used for both wet and dry granulation processes, making it a valuable tool for many industries. It is designed to comply with Good Manufacturing Practice (GMP) requirements and ensure that product contact parts are completely separated from technical components, providing a clean and oil/grease-free operating chamber.

The main functions of PMS Granulator® are to reduce particle sizes of agglomerates to a desired dimension and improve particle size distribution. This is achieved through screen mesh selection and gap setting between the rotor and screen, which allows for precise control over the particle size.

Agglomerates are fed through the top inlet hopper and flow into the granulating chamber, where continuous shearing force is applied to press out granules through wire mesh (for dry granulation) or a cylindrical shredder (for wet granulation). The resulting refined particles are then discharged through the bottom port into a product container.

Overall, PMS Granulator® is a reliable and efficient machine that can greatly improve the efficiency of particle size reduction and granulation processes, while ensuring a high level of quality and compliance with industry standards. PMS offers 4 Sizes of the Machines to accommodate from laboratory use to large production.

APPLICATION

Pharmaceuticals: Granulation and Size Reduction for APIs, excipients,

Herbal Products: Grinding Herb and Plant Material, Reduce Particle Size of Herbal Extracts, Preparing Herbal Powder

Food: Grinding of Spices, Sugar, Sweetener, Dried Food, and Coffee Beans

Agricultural: Grinding Grains, Hay, Straw for Animal Feed, Shredding Agricultural by Products to Make Biomass Fuel

Others: Grinding Plastic for Recycling, Grinding Fish Bone for Animal Feed

BENEFITS

cGMP Compliance: Ensure the safety and quality of products produced

Energy Efficient and Fast Process Time.

Improve Flowability: Make the products easy to be handled in the subsequential processes.

Uniform Size: Allow precise control over particle sizes, which is critical for pharmaceutical industry.

Easy to Scale: The Process is easily scalable from lab to large production scales.

Easy to Operate, Clean and Maintenance: It requires a litter training to be used proficiently.

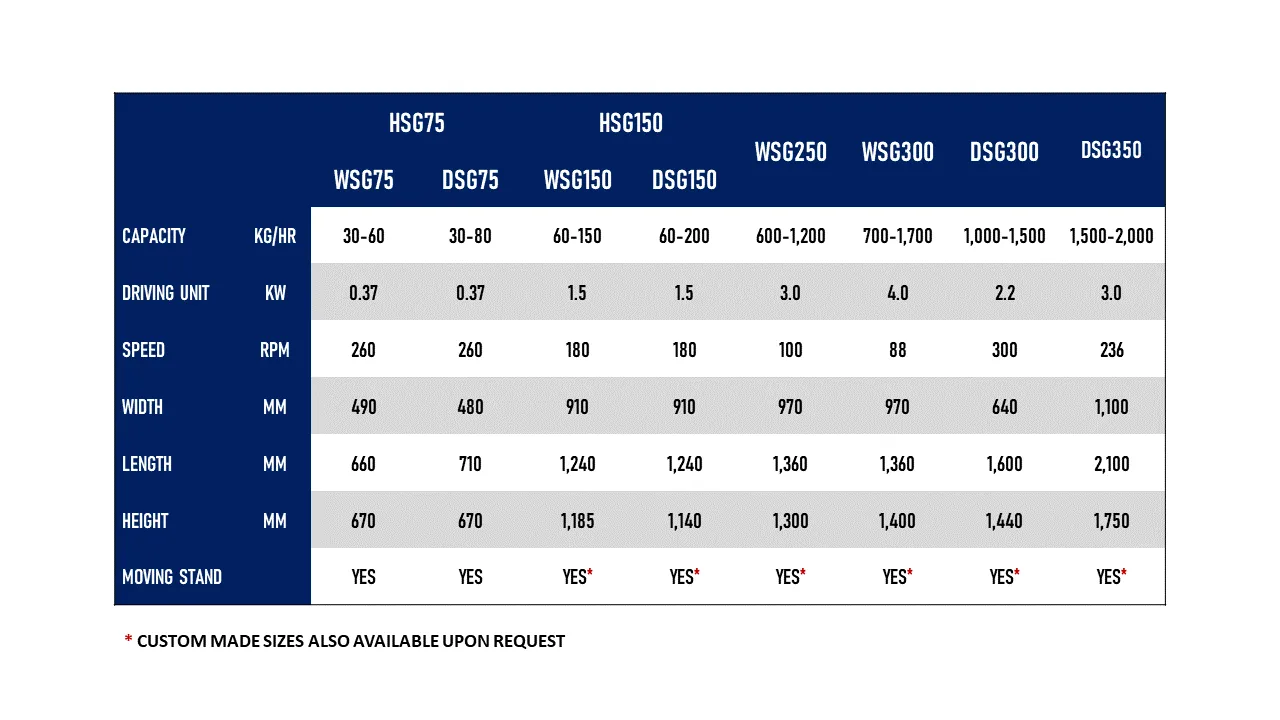

SPECIFICATION

STANDARD

Contacted Parts are made of Stainless Steel 316

Variable Speed using Inverter

Explosion Proof Motor / Explosion Proof Controller

Inert Gas Blanketed for Hazardous Material

Product Container

Installation on Platform

Additional Stainless Steel Screens

Special Loading and Discharge Features

Validation Documents: Installation Qualification / Operational Qualification

18/88-89 M.6 Khok Krabue, Mueang

Samut Sakhon, THAILAND 74000

Phone: +66 2 284 2159 TO 62

Email: [email protected]

© 2020 PMS. All Rights Reserved